Home » Construction Management (Page 3)

Category Archives: Construction Management

Cat’s Connected Worker Puts Safety In a Hard Hat, Wearable Tag

Embedding tracking and communication capabilities into PPE just makes sense.

Cat says its new Connected Worker system, which will be available during the first quarter of 2022, combines smart wearable technology with the power of analytics to make workers safer. The system was developed by GuardHat.

Introduced at MINExpo this week, the Connected Worker consists of three major components: the wearable hardware, software that captures and reports data and an Internet of Things platform that receives field reports and alerts workers of potential safety risks.The system communicates evacuation orders, fall detections, SOS signals and geofence violations.

The lithium-ion battery backs last 8-12 hours and can be easily swapped out.GuardHatThe “wearable” part comes in two different forms: an HC1 Hardhat has an embedded GNSS chip that tells users where each wearer is on site. Users employing Ultra-Wideband systems can also track wearers indoors, offering 3D tracking (longitude, latitude and elevation) to quickly locate workers in an emergency. The hard hat features video and audio call, push-to-talk and offline geofence and recording capabilities.

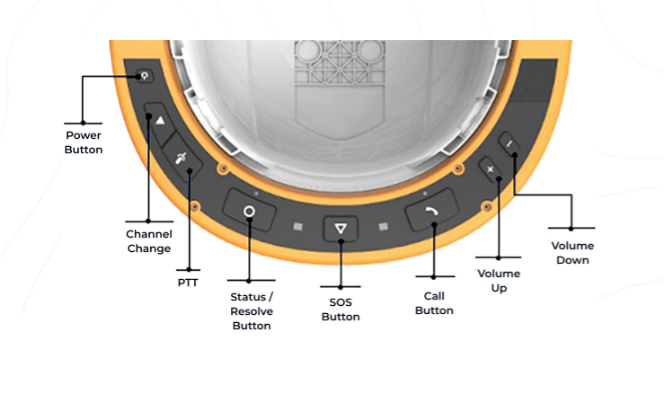

According the the GuardHat website, the HC1 Hardhat is powered by a rear lithium-ion battery pack that provides 8-12 hours of power. The yellow brim is where most of the features reside. Buttons on the underside of the brim include a call button, volume, SOS, status/resolve, push-to-talk, channel change and power button. The maximum weight of the hard hat (with suspension) is 1 pound, 12.2 ounces.

The Cat Connected Worker TA1 tag offers GNSS and Bluetooth tracking outdoors.CaterpillarAnother wearable is the TA1 tag, which offers GNSS and Bluetooth tracking outdoors. The tag has SOS, evacuation and social distancing alerts and notifies workers of geofence breaches. The tag can also capture images and videos to report hazards that are automatically shared with the system’s safety control center (SCS) to teams can quickly develop geofences around the hazard.

The system, part of Cat’s MineStar Detect portfolio, also has an Android smart phone app to monitor crews outdoors. It allows field managers to communicate with workers, issue SOS alerts, and can capture images and videos.

Cat says Connected Worker creates a safety ecosystem at the mine site, capturing and storing data either in the cloud or on a local server for analysis. Using the SCS, managers can view worker location and data in near real-time to communicate unsafe situations to those in the field. Reports include event reporting, violations and emergency evacuations, location reports with heat signatures that designate highly traveled areas, sensor readings that include temperature, noise, humidity and pressure.

Smart hard hats are gaining traction, especially in the mining sector. The SmartCap, now marketed by the Wenco International Mining Systems division of Hitachi Construction Machinery, attacks a different safety issue: fatigue. It measures alertness and fatigue by analyzing brain activity, often referred to as EEG. Alertness scores, early warning alerts and fatigue alarms are delivered via a smartphone app installed on rugged devices.

Did you miss our previous article…

https://www.tortowheaton.com/?p=255

Volvo CE in Field Trials for Excavator System That Cuts Energy Losses

A Volvo Construction Equipment team from Sweden and South Korea has been quietly working with Finnish company Norrhydro to develop an electro-hydraulic system that promises to drastically cut energy losses and improve fuel efficiency in its excavators.

In a manner similar to common rail fuel systems, all the excavator’s work functions are connected to a hydraulic accumulator via a common pressure rail and two or more pressure lines. These accumulators recover kinetic energy and peak power supply that is normally lost in a conventional system. For cylinder-driven work, “smart actuators” convert hydraulic power to variable force and speed. Energy recovery through the system also boosts the performance and efficiency of the machine’s swing function.

All this energy efficiency translates into a smaller engine and cooling system doing the same work as a larger system, which ultimately results in more work done for less fuel and fewer greenhouse gasses. Additionally, with greater power on tap, cycle times can be shortened, for example when loading a truck, which contributes overall efficiency to the work and cost benefits to the contractor.

Volvo is currently conducting customer trials in the field, and it is expected to accelerate the introduction of the system across Volvo CE’s large excavator platform, with availability coming in the near future. The new electro-hydraulic system is part of Volvo’s e-mobility program to increase fuel efficiency and reach the Volvo’s ultimate goal of net-zero emissions operations.

When a Compact Loader Just Won’t Do: Wheel Loaders Still Hold Sway on Jobsite

Though compact loaders continue to gain in popularity, standard wheel loaders are still a staple on the jobsite, thanks to their heavy-duty loading abilities.

But just as their compact equivalents are becoming more versatile and adding new technology, so too are these trusty workhorses.

The newest models are coming with such features as obstacle detection, tablet-like touchscreen displays and a variety of attachments.

Juston Thompson, senior product manager, Hyundai Construction Equipment Americas, says machines up to 3.5 cubic yards are more likely to be used with attachments such as mulchers, buckets with thumbs or grapples, and rakes. “Compared to compact equipment, small- to mid-size wheel loaders offer more capacity in these applications,” he says.

And speaking of buckets, one manufacturer has even come out with a “transparent” one, using advanced technology that enables the operator views into the typical blind spots.

For customers considering a wheel loader in addition to or instead of a compact loader, John Dotto, product application and training specialist, Wacker Neuson, suggests three key considerations:

First, is the wheel loader compatible with the attachment now in use or projected for future use?

Two, can you trailer a wheel loader, which is likely longer, wider and taller than a skid steer?

Three, given that the learning curve to operate a wheel loader is shorter than for a skid steer or compact track loader, is that an advantage for your operation? If you have frequent turnover and often have lesser-skilled operators, the relative simplicity of a wheel loader can be a real advantage.

Here’s a look at the latest models and features from some of the top manufacturers:

Cat’s new models

The new Cat 980 and 982 have Cat Payload, which includes low-lift-weigh and manual tip-off functions. Optional Cat Advanced Payload adds Lists-Management, Multitask- and Manual-Add Modes and Tip-off assist.

The 980 XE and 982 XE models have continuously variable transmissions, the first in this size class. The design uses a direct mechanical path from the engine to the wheels with a Hystat variator and can improve fuel efficiency up to 35%.

The 980 and 982 models have 1,000-hour maintenance intervals. Remote Troubleshoot allows remote diagnostics, while Remote Flash ensures machines are running the most up-to-date software. Customers can install updates at the best time for their operations through the Cat Remote Services Web Portal.

With Autodig, the entire bucket loading cycle can be automated, while Autodig with Auto Set Tires can significantly reduce tire slip.

Doosan’s “transparent bucket”

Cabs on the new -7 Series machines from Doosan have 14% more glass, improved HVAC airflow and an adjustable 8-inch monitor with integrated rear-camera view.

All Doosan -7 Series wheel loaders have the same cab layout with important and frequently used controls relocated for more intuitive access, a standard variable-speed, reversible fan that is adjustable from the Doosan Smart Touch screen, an optional automatic lubrication system and the Doosan Smart Guidance System that helps operators improve their efficiency.DoosanDoosan’s Situation Awareness Technology (SAT) 2.0 monitors multiple systems to provide optimal performance and fuel efficiency. The operator can tap a button or push the accelerator past a detent to move up one mode (Economy to Normal or Normal to Power).

Doosan’s Transparent Bucket uses one camera mounted low on the frame and a second mounted high on the cab. Software stitches together the two views to enhance visibility in front of the bucket. The system also has object detection.

Transparent Bucket can be retrofitted to existing machines with a kit that includes a monitor and an electronics module that interfaces with the loader’s CAN bus.

“Doosan is working toward our Concept-X integration and automation of the worksite,” says Aaron Kleingartner, dealer and product marketing manager, Doosan Infracore North America. “Our Transparent Bucket feature fits right in with that.”

Customer feedback drives Case updates

Case G Series loaders have updated features including a tablet-like touchscreen display, configurable buttons in the armrest, adjustable electrohydraulic controls and a fully integrated OEM payload system that improves load accuracy and provides detailed reporting.

Case G Series loaders have a new touchscreen display that provides machine information and convenient access to operational controls, a new Smart Power Mode with enhanced communication between the engine and transmission to improve fuel efficiency and reduce wear, and enhanced telematics and integration with the Case North American Uptime Center.Case CEAlso new is the tire pressure monitoring system that shows pressures on the display and issues an alert for out-of-range readings. Power modes have been reduced to two: Smart and Max.

“These features came from feedback from customers and dealers,” says Andrew Dargatz, product manager, Case. “The result is increased productivity and uptime with decreased operational elements that hinder performance and profitability.”

Mecalac goes bigger

The AS1600 swing loader has been Mecalac’s only non-compact model. The company is now bringing its larger AS210 swing loader to North America.

The AS210 is Mecalac’s largest swing loader. Bucket capacity range is 2.7 to 3.9 cubic yards. Operating weight is 33,069 pounds. It is powered by a Deutz turbo diesel engine rated at 175 horsepower. Dump height is 134 inches. Turning radius is 16 feet 4 inches, thanks to four-wheel steering.MecalacThe appearance of the AS210 is unlike other Mecalac models, more angular and less flowing. “It was always intended to be a machine for heavier-duty applications, and it looks the part,” says Peter Bigwood, general manager, Mecalac North America.

As with other Mecalac swing loaders, the AS210 provides 90 degrees of loader swing left and right, has a non-articulated frame, and three-mode, four-wheel steering.

“The AS210 brings extra capacity to applications where the swing design is especially helpful such as backfilling and road jobs where it reduces the need for lane closures,” Bigwood says.

Deere’s three tiers

Deere is introducing its performance tiering strategy with wheel loaders. The G, P and X tier progress from basic, economical machines through machines with improved performance and comfort to machines with the latest features and technology Deere offers.

The 644 is the first John Deere wheel loader to be available in G, P and X tiers. The 644 X and P machines are now available for purchase in the U.S. and Canada; the 644 G machine is available in Canada and other global markets. Bucket capacities for the P and X tier machines are 4 to 4.75 cubic yards. (4.25 cubic yards G tier). Net power is 249 horsepower for the P and 231 for the X (227 horsepower for G tier).John DeereAs with its predecessors the 644K and 644L, the current 644 is an E-Drive hybrid with an engine-driven generator, an inverter, an electric motor and a PowerShift transmission specially optimized for use with the hybrid design. The 944K is also an E-Drive machine but uses four electric wheel motors.

Current Deere models 444 through 744 will be available in G, P and X tiers. “Those are recent models with no need for extensive modification to fit into Deere’s new tier structure,” says Luke Gribble, solutions marketing manager, Deere.

Komatsu’s transmission advancements

“Most wheel loaders are used as loaders and are designed to feed a process,” says Nathan Repp, product marketing manager of Komatsu’s WA200-8 through WA320-8. “However, all Komatsu loaders have optional auxiliary hydraulics for use with attachments and specialty buckets.”

The Komatsu WA475-10 has 22% more horsepower than the WA470-8 yet achieves up to 30% better fuel efficiency, thanks to the Komatsu Hydraulic Mechanical Transmission. KHMT also offers dynamic braking to reduce brake wear. Boom lift force is increased by 20% and breakout force by 8%. The new bucket design improves pile penetration and material retention.KomatsuAdam Brown, product marketing manager for Komatsu models WA320-8 through WA500-8, says the WA475-10 is the first of a new design and features the Komatsu Hydraulic Mechanical Transmission. The KHMT is a planetary gear design and provides stepless shifting. A dial sets a maximum travel speed while allowing full stroke of the accelerator for more precise control.

Other improvements include better ergonomics for the controls and switches, more glass area in the cab, and placement of the mirrors and rearview camera monitor at eye level.

Hyundai’s All-Around View

Hyundai HL900 series loaders have standard bucket capacities of 3 to 7.1 cubic yards. All models are available with standard or extended reach (XT) Z-bar linkage configuration. The HL940TM and HL955TM Tool Master models use a parallel linkage for greater lift capacity, improved load stability, rapid dumping capability and enhanced visibility.HyundaiHyundai Construction Equipment Americas’ A Series loaders feature enhanced onboard weighing that displays what’s in the bucket plus what’s in the truck. Names and target loads can be assigned to individual trucks.

An optional second monitor can be dedicated to the 360-degree, four-camera All-Around View Monitoring (AAVM) feature. The rearview system includes object detection. An optional radar further enhances safety.

Liebherr camera technology

The L580 features Liebherr’s XPower continuous power split driveline. XPower is fully automatic and has no traction interruptions across the entire speed range (up to 24.9 mph forward and reverse). Power is from an inline 6-cylinder engine rated at 312 horsepower. Bucket capacity is 7.5 cubic yards, and operating weight is up to 63,490 pounds.LiebherrOptional Active Personnel Detection is now available on Liebherr wheel loaders to monitor the area behind the loader.

Brake assistant uses camera technology and distinguishes between people and inanimate objects. Warnings can be evaluated using LiDAT, Liebherr’s telematics system.

Optional joystick steering is available, and customers can opt for joystick steering only, with no steering wheel or column.

LiuGong’s gradual rollout

“Demand for new applications started coming in late 2018,” says Hugo Chang, wheel loader product manager, LiuGong North America.

All LiuGong wheel loaders have third-spool hydraulics. Smaller models are plumbed to the end of the loader arms because they use quick connects, which require hydraulics.

The LiuGong 848H is powered by a Cummins QSB6.7 engine rated at 175 horsepower and has a ZF powershift transmission. Operating weight is 35,260 pounds, and bucket capacity is 3.5 cubic yards. Switching attachments is easy with the quick coupler, and the Z-bar linkage yields high breakout forces and stable material transport with minimal spillage.LiuGongLarger machines, which use pin-on buckets, are plumbed to a midpoint on the arms. Pilot controls are used for lift and tilt while an electrohydraulic thumbwheel controls the third valve. The company’s two largest models, the 877H and 890H, are fully electrohydraulic.

Chang says new model introductions usually coincide with emerging emissions regulations. Their current Tier 4 Final models came to market in 2016 and are being replaced with European Stage V machines. Because there is no U.S. equivalent to Stage V – that is, no Tier 5 – there is no deadline for introduction and therefore no urgency to bring these models to market.

“This gradual rollout allows us to implement the change to best benefit LiuGong, our dealers and our customers,” says Chang. “All our North America wheel loaders will likely be Stage V machines by 2023.”

Volvo boom kickout, return-to-dig

Boom kickout and return-to-dig are key features on Volvo loaders. Boom kickout height is set by the operator and is operated with a single stroke of the lever.

Volvo Construction Equipment is making its Load Assist machine control compatible with wheel loaders from the L60H to the L350H, including the L220H shown. Load Assist apps are operated via the Volvo Co-Pilot through the in-cab, 10-inch, high-resolution monitor. Calculator, Notes and Weather are called Toolbox Applications; tire pressure monitoring is also included. The Map app gives machine position and inter-machine telecommunication to provide real-time site activity.Volvo CE“It’s especially helpful when loading trucks at the same height for extended periods of time,” says Eric Yeomans, product manager for wheel loaders, Volvo CE North America.

Return-to-dig puts the bucket at the same position, again with a single lever stroke. Control sensitivity can be set to Soft, Normal or Active.

Lockup characteristics of Volvo models L110H through L260H can be set by the operator using OptiShift. The new lockup torque converter coupled with Volvo’s Reverse By Braking feature provides smoother directional changes, less driveline strain and greater fuel efficiency.

Wacker Neuson eases attachment switches

The largest Wacker Neuson articulated loader, the WL95, has a 2-cubic-yard bucket, 136-horsepower engine and Ecospeed PRO continuously variable hydrostatic transmission providing travel speeds of up to 24.8 mph. Flow to attachments can be easily adjusted using a jog dial. The articulation joint and pendulum rear axle provide a 96.5-inch inside turning radius with optimal traction.Wacker NeusonWacker Neuson puts a universal skid-style plate on smaller loaders, allowing attachments to be changed from the operator’s seat.

As the name suggests, this mounting plate is compatible with a range of attachments and work tools used with skid steer and compact track loaders.

Electrical and hydraulic connectors are standardized across Wacker Neuson models to further enhance compatibility.

Hitachi offers control options

Michael Winfield, product and applications manager, Hitachi Construction Machinery America (HCMA), says control configuration options vary by model. They can include three-spool control valve with multifunction and auxiliary levers; three-spool with two levers; four-spool with multifunction and auxiliary joystick; and four-spool with two levers and two auxiliary levers.

Key features on the Hitachi ZW220-6 include lift arm auto lever that allows the operator to set boom kickout via the multifunction screen, joystick steering, parallel/tandem hydraulics for more efficient lifting and dumping and a shift-to-hold switch that overrides automatic settings and allows the operator to hold the transmission in its current gear.HitachiApproach Speed Control automatically increases lift-arm speed while maintaining drive speed, and Intuitive Rim Pull Control provides additional power as required to boost breakout force in digging applications. Torque proportioned differentials minimize wheel slippage.

HCMA features also include ground-level-accessible grease points and an automatic reversible cooling fan and wide-fin cooling core.

Yanmar adds comfort

The V12 is Yanmar’s biggest wheel loader. Bucket capacity if from 1.57 to 2.35 cubic yards. Operating weight of this 100-horsepower loader is 15,432 pounds. A quick coupler is standard as is joystick control with third and fourth control circuit in one hand. Both axles have automatic-locking differentials. Hydrostatic drive provides infinitely variable speed control forward and reverse as well as an inching pedal.YanmarYanmar has one model in this size class, the V12. Its rubber-mounted cab includes HVAC, extra high-back suspension seating with lumbar support and two doors for easy access.

The joystick provides third- and fourth-spool controls. A central lubrication system is available.

Takeuchi focuses on owner-operators

Takeuchi also has one model in this range, the TW95. Features include a cab with air-ride suspension seating, two-speed travel and an inching pedal.

Top travel speed is nearly 25 mph; the inching pedal maintains engine speed while metering travel speed.

The Takeuchi TW95 is powered by a Deutz TCD 3.6 liter inline 4-cylinder engine rated at 114 horsepower. Differentials are 100% locking; 12 degrees of center pin oscillation allows equipment movement while keeping the operator’s station stable. Hydrostatic drive provides up to 24.8 mph travel speed and dynamic braking, slowing the loader as the operator backs off the throttle. Linkage is Z-bar for greater breakout and loader arm forces.TakeuchiStandard automation features include boom height kickout, return-to-dig and automatic bucket positioning.

“We make all our wheel loaders comfortable and easy to operate since many are purchased by owner-operators,” says Lee Padgett, product manager.

Product Briefs: Explore Virtual Lift Scenarios with JLG’s Access Your World

JLG has added a new educational module to its virtual training and education portal Access Your World. This third virtual environment features finish and maintenance work taking place within an office environment. In it users can explore a wide range of content on JLG products including low-level access, scissor lifts, atrium lifts and the JLG Augmented reality App.

The other two scenarios include construction tasks on the outside of a stadium, such as site preparation and steel erection work; and truss, fit out and finish work inside the stadium. All three scenarios are designed to illustrate multiple stages of construction and help users better understand specific applications and uses of the equipment.

Soil Connect adds new eTicket functionality

SoilConnectSoil Connect had added a few feature, Quick eTickets, to its eTicket platform that allows users to easily capture customer information, type of truck, destination, pictures, eSignatures, type of material, load count and other types of information in real time on an as-needed basis. The system simplifies the ticketing process for everyone and eliminates administrative expenses.

“Quick eTickets is for on-the-fly situations that drivers often encounter on a daily basis,” says Cliff Fetner, founder and CEO of Soil Connect.

eTickets is a contactless, e-ticketing platform designed to eliminate the use of paper tickets and allow users to easily capture customer information, type of truck, destination, pictures, eSignatures, type of material, load count and other critical business information.

Extendable trailers meet California haul requirements

The Fontaine Xcalibur trailer opens to 90 feet.

Fontaine Heavy-Haul introduced the 53-foot Xcalibur extendable trailer that opens to 90 feet. The new models offer a choice of spring or air suspension.

When the trailers are closed and the sliding axles are in their most forward position, the distance between the kingpin and the rear axle center is less than 40 feet, making these trailers legal to operate in California. A cable management system helps protect telescoping air and electrical lines from damage. Sliding axles are attached to the trailer in a slider box so they move together as a unit.

For greater strength and durability, steel I-Beam crossmembers are welded on 12-inch centers. Steel reinforced main beams, structural steel siderails and steel front & rear skirts complete the heavy-duty design.

Did you miss our previous article…

https://www.tortowheaton.com/?p=164

Product Roundup: Deere Forges Agreement on Towed Scrapers

John Deere has announced a master supply agreement with Mobile Track Solutions, to develop Deere-branded towed scrapers to be distributed through John Deere’s construction and agriculture dealer networks. Through the agreement, Mobile Track Solutions will supply greater than 27 cubic yard capacity towed scrapers to be used with John Deere 460E-II articulated dump trucks and 9R series scraper tractors.

Deere now manufactures 10 models of 15 to 24-cubic-yard heaped capacity towed scrapers.

The John Deere-branded scrapers will be compatible with its new technology solutions, including an earthmoving productivity system, which debuted at ConExpo 2020. The new technology offerings will include obstacle intelligence and rear object detection, SmartWeigh, SmartAttach and a new scraper earthmoving productivity system.

Husqvarna debuts new saw and battery platform

Husqvarna’s new battery system will match power outputs of gasoline-based models.Husqvarna

Shown at the World of Concrete, the Husqvarna usqHK1 PACE concrete saw is equipped with a new PACE battery system and an X-Halt brake function capable of stopping the rotation of a blade in a fraction of a second for enhanced safety. The PACE battery system that powers the K1 saw will also be used in additional Husqvarna products to come. The saw’s diamond blades in 12- and 14-inch sizes have been optimized for battery operation.

Tadano upgrades cranes

ACR.110-1Tadano

Mobile crane manufacturer Tadano has upgraded its four-axle and five-axle cranes in the 110- to 130-ton (US) class. The maneuverable AC 4.110-1 now has a larger lifting capacity without any changes to its total weight – thanks to a new and stronger boom that is also part of the five-axle AC 5.120-1. As part of its reorganization efforts, Tadano will be standardizing the names of its mobile crane models throughout the year. The new AC 4.110-1 and AC 5.120-1 come with updated names from the start.

Did you miss our previous article…

https://www.tortowheaton.com/?p=128

Joystick Steering Available on Cat’s New MH3022, MH3024 Material Handlers

A comfortable operator is a productive operator. That’s the thinking behind the new Next Generation material handlers from Cat.

The Cat MH3022 and MH3024 offer a choice between deluxe and premium designs. The new Next Generation cab features a joystick steering option, eliminating the steering column to improve forward visibility, legroom and ease of cab entry. The left-hand console tilts up, and all controls are positioned in front of and within easy reach of the operator to avoid unnecessary movements.

A heavy-lift mode on both models boosts lifting capacities to more efficiently handle big loads. By allowing the boom to freely travel up and down without using pump flow, the standard SmartBoom enables the operator to focus on grapple control and maintain a smoother cycle.

On the MH3022 a 12% wider footprint increases the stability of the machine for improved performance when lifting at extended reach. The MH3024 offers up to 7% greater swing torque to move more material faster. Both material handlers can be equipped with a 15-kilowatt generator for magnet operation.

These Next Generation material handlers are powered by the Cat C4.4 engine, capable of operating on up to B20 biodiesel, and the engine’s maintenance-free aftertreatment system lowers operating costs and increases machine uptime.

A choice between power and eco modes closely matches the needs of every lift and, according to the company, reduces fuel consumption by 10% without sacrificing machine performance.

A 10-inch high-resolution touchscreen monitor with jog-dial offers is used to navigate the operator controls. Different machine operators can store their specific joystick and preferred power mode settings, and the machine automatically recalls the settings based on the Operator ID.

Did you miss our previous article…

https://www.tortowheaton.com/?p=101

Hyundai Buys Doosan’s Construction Equipment Division

Hyundai Heavy Industries’ purchase of Doosan Infracore became official today, potentially boosting the combined company into the top 10 construction equipment manufacturers globally.

Doosan Infracore will become a subsidiary of the new Hyundai Genuine group. Hyundai Construction Equipment will also be a subsidiary.

Both South Korean-based Hyundai and Doosan construction subsidiaries will operate independently, Doosan says.

Hyundai acquired a controlling 30% stake in Doosan for 850 billion won ($722.5 million), according to The Korea Herald.

The deal includes all of Doosan’s construction equipment but not Bobcat, which Doosan acquired in 2007. Doosan Bobcat and Doosan Infracore North America separated their businesses in 2018.

Doosan and Hyundai subsidiaries will independently “grow together, complement each other, even compete in good faith in all areas, including technology, production, purchasing, sales and quality,” Doosan said in a news release. “This will enable our business to expand and associate with other companies operated by the whole HHI group.”

Hyundai and Doosan would operate independently as subsidiaries under the purchase agreement, according to Doosan.HyundaiDoosan has said there is no intent to merge Hyundai and Doosan subsidiaries.

“It is important to note that this acquisition is being conducted by HHIH (Hyundai Heavy Industries Holdings), and not Hyundai Construction Equipment (HCE),” says a previous Doosan statement. “Under the terms of the deal, the intent is for Doosan Infracore and HCE to operate as independent companies under HHIH. There are currently no plans to merge HCE or Doosan Infracore. Both companies, along with their people, dealer networks and brands, will be kept independent from one another once the sale is final.”

Doosan says it plans to focus on commercializing its Concept-X, which combines artificial intelligence and information and communications technology, as well as advancing other technologies, such as electric excavators, battery packs and hybrid fuel cells.

“Together the two brands will combine as a global top player, putting us much closer to achieving the goal of becoming a global top 5 player,” Doosan says.

The purchase of Doosan Infracore could raise the new Hyundai Genuine group to sixth place globally for construction equipment sales, capturing 4.9% of total global sales, based on the 2021 KHL Yellow Table.

Doosan currently has $7.1 billion in sales and is ranked ninth, while Hyundai has sales of $2.3 billion and is ranked 22nd, according to the Yellow Table.

The deal came after Doosan Infracore’s parent, Doosan Heavy Industries & Construction, sought to sell its construction segment to pay off heavy debts it had incurred. One stumbling block to the deal had been a legal dispute with Doosan Infracore China’s minority shareholders. The company recently repurchased a 20% stake in the Chinese subsidiary to settle the dispute and clear the way for the Hyundai deal, according to The Korea Herald.

Did you miss our previous article…

https://www.tortowheaton.com/?p=98

Industry Roundup: Alta Equipment Takes on Nikola Electric Heavy Truck Line

Alta Equipment Group has added Nikola’s battery-electric Class 8 truck line, and will offer sales and service for the trucks in New York, New Jersey, eastern Pennsylvania and areas in New England.

Ryan Greenawalt, Alta CEO, says the firm views the Class 8 market as “having strong long-term potential and an excellent fit with our commercial vehicle eMobility growth strategy.”

In addition, says Greenawalt, the move “aligns well with our long-term strategy as we aim to diversify our business into high growth industries, with exclusive territories anchored by premier partners.”

“Alta Equipment is an exceptional addition to our already impressive list of 116 dealer locations within the Nikola sales and service dealer network,” says Pablo Koziner, Nikola president, energy and commercial. “The Nikola partnership should complement Alta’s history of battery-electric and hydrogen fuel-cell technology via their materials handling business and add to its growing eMobility vertical by fulfilling its long-term commitment to clean technologies.”

Q2 results: Alta, which serves as the Volvo Construction Equipment dealer throughout much of its territory, also announced Q2 results, saying it had seen its construction segment grow 37.2% during the quarter compared with the same period last year.

“Geographically we saw continued strength from Florida in our construction segment overall and are beginning to see some positive trends out of the New York region which was acquired last December,” Greenawalt said during the firm’s Q2 earnings call.

“On the M&A front,” Greenawalt said, “our pipeline remains strong and we continue to be in active discussions with other equipment dealers in both our construction and material handling businesses.”

Brandt Tractor buys Cervus Equipment

John Deere dealer Brandt Tractor has acquired fellow Deere dealer Cervus Equipment in a $302 cash deal.

“The Brandt team is excited about this deal as it will allow us to better serve our customer base across Canada,” says Shaun Semple, Brandt CEO. “The addition of Cervus’ offerings will form three brand new segments at Brandt dedicated to serving the agriculture, transportation and material handling industries. These segments, in addition to our existing specializations in construction, road building, forestry and more, will further establish Brandt as a total solutions provider across our diverse customer groups.”

In addition to Canada, Cervus also has operations in Australia and New Zealand. Brandt is headquartered in Regina, Saskatchewan, and is the world’s largest privately-owned John Deere Construction & Forestry equipment dealer.

The deal is expected to close in the fourth quarter.

Finning posts 30% Q2 revenue increase

Caterpillar dealer Finning says it posted a 30% year-over-year Q2 increase while noting the pandemic impacts felt during the same time last year. The firm, headquartered in Canada, also has operations in the United Kingdom, Ireland, and South America.

In Canada, net revenues increased by 25%, “driven by strong demand for new construction equipment in a recovering market and higher product support activity,” Finning says, saying it added 30 technicians during the quarter.

It also noted that 2021 net revenues are still 18% lower than those in Q2 2019.

MANUFACTURERS, SUPPLIERS

Kubota: CTL, skid steer production will begin at Kansas plant in 2022

Construction equipment production at Kubota’s 750,000-square-foot Salina, Kansas, facility will begin in the second half of 2022, according to remarks made by Kubota executives to the Salina Journal. The facility is also the headquarters of Great Plains Manufacturing, an agricultural and construction attachment manufacturer purchased by Kubota in 2016.

The plant will house the Kubota Construction Equipment Research and Development Center, and is designed in part to shorten equipment delivery times to North American dealers.

Once construction equipment production starts, Kubota expects to have 135 employees working at the center. In total, Kubota expects the entire facility to grow to 2,110 workers by 2025.

Liebherr USA partners with Advanced Technical Institute

Liebherr USA

Liebherr USA has launched a partnership with Advanced Technology Institute to host up to six students each year who are studying to be service technicians.

Liebherr will also sponsor ATI’s hydraulics program and made a L 526 wheel loader available for student training. The partnership allows ATI students to become Liebherr certified as part of their program completion. After completing the co-op program, Liebherr is offering a signing bonus of 50% of tuition charges for eligible new hires that accept full-time employment.

Did you miss our previous article…

https://www.tortowheaton.com/?p=63